How are screws manufactured?

Using great force, 3 fundamental cold forming processes transform wire into a head, drill point, and thread.

At ASTON SWEDEN we are specialists in cold forming of self-tapping and self-drilling screws in aluminum and stainless steel.

Screws are made from stainless steel or aluminum wire coils. The wire is carefully chosen to match the design and application of the screw.

The wire is fed to the heading machine, which straightens and cuts the wire into a blank. The blank is then punched twice where the first punch partly shapes the head. The second punch forms the final head shape including a potential recess.

The drill point is shaped by punching two dies closely together around the tip of the headed blank, deforming the tip of the blank into the desired drill point.

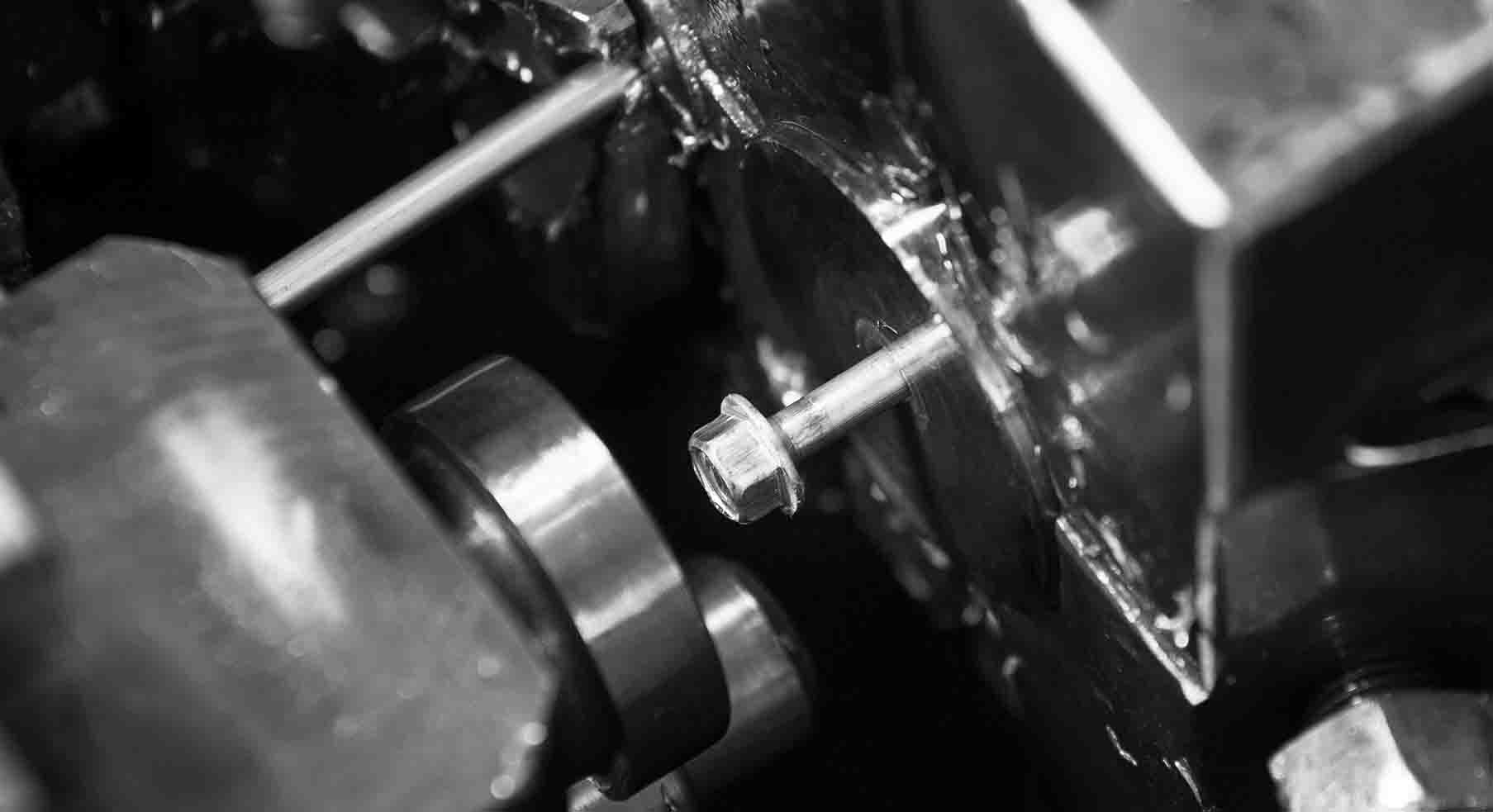

The threads on the screw are formed by rolling the screw between two flat-dies with the desired thread design, giving the screw its characteristic look, and getting rid of excess material from the pointing process.