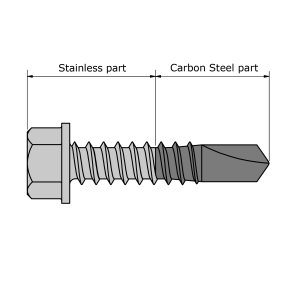

bi-metal

A bi-metal screw combines the best of two worlds – hardenable carbon steel and austenitic stainless steel. The stainless part is ductile and very corrosion-resistant, but it is too soft to be used in self-drilling screws for steel. For this reason, we make bi-metal screws, where the drill point and the first few threads are made of hardenable steel, while the rest of the screw is pure stainless steel.

Manufacturing of Bi-metal

Manufacturing bi-metal screws of high, uniform quality is a very special discipline that requires great technical and practical know-how. In its simplest form, it can be boiled down to six manufacturing steps:

- Cold forging the head of the stainless part

- Welding together the stainless part and the carbon steel part

- Cold forming the drill point

- Threading the screw

- Hardening of the carbon steel part – the drill point and the first couple of threads

- Surface treatment